Use of raw material with high damping capacity and low thermal expansion for machine tools leads to improvements in machining precision.

| Type A | Type B | |

| Tensile strength (N/mm2) | 150-170 | 350-400 |

| Hardness (HB) | 110-130 | 165-180 |

| Elongation (%) | - | 6-12 |

| Specific gravity | 7.75 | 7.80 |

| Thermal expansion coefficient [(x10-6] *2 | 3.0-3.6 | 3.3-4.3 |

| Thermal conductivity (cal/C.S.C) | 0.06-0.07 | 0.06-0.07 |

*1 Test results by separately sampled test pieces (Y block of JIS Type B)

*2 Thermal expansion coefficient of gray cast iron is approx. 11.0x10-6-6

Damping capacity was increased while still securing strength and machinability equivalent to those of gray cast iron. Application in parts requiring damping capacity enables the expectation of precision improvements in the machine itself.

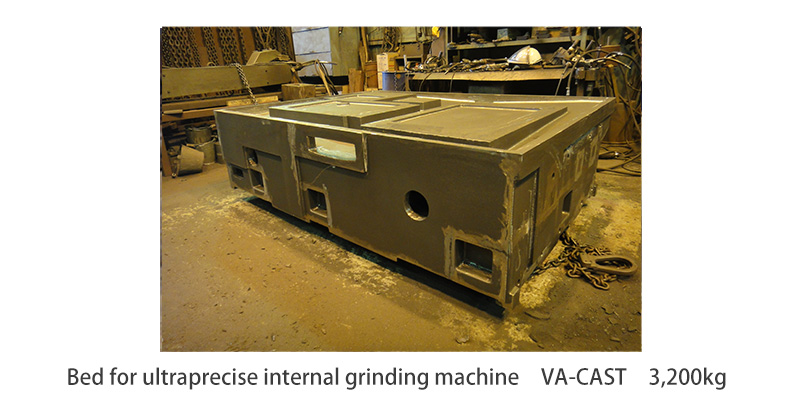

| VA-CAST | 18.4 |

|---|---|

| Gray cast iron | 3.5 |

| Spheroidal graphite cast iron | 1.5 |

*Comparison based on our products

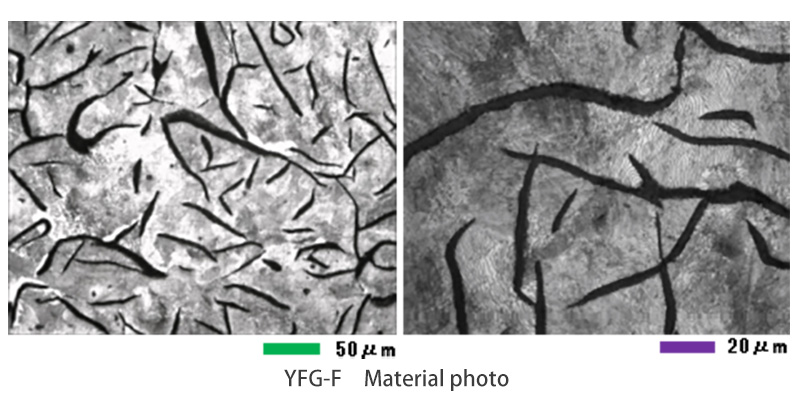

This material has strength equivalent to JIS FC300 with carbon content equivalent to our products made of JIS FC200 to FC250. The high carbon content allows precipitation of a large amount of fine Type A graphite to realize excellent machinability and processability. The compact pearlite of the base material structure achieved by our unique melting technology increased both strength and hardness. The material also increases grinding efficiency in the lapping (finish) process when grinding ball bearings.

| Tensile strength (N/mm2) | 280-320 |

|---|---|

| Hardness (HB) | 180-220 |

| Pearlite ratio | 85%+ |

* Test results using separately sampled test pieces (Test piece of JIS Type 8)

New melting technology to promote the precipitation of fine graphite and make the base material structure more compact was obtained from the development of YFG-F (Yukawa Fine Graphite cast iron - Flaky) and added to conventional products made of Ni-Cr-Mo cast iron, which has been manufactured for the flushing (deburring) and grinding (rough grinding) processes when grinding ball bearings to achieve higher quality material. Since use after oil quenching is presumed, the material is manufactured using the composition that has been selected with consideration for high quenchability.

| Tensile strength (N/mm2) | 380-450 |

|---|---|

| Hardness as cast actual product (HS) | 36-40 |

| Hardness of actual product after oil quenching (HS) | 75-85 |

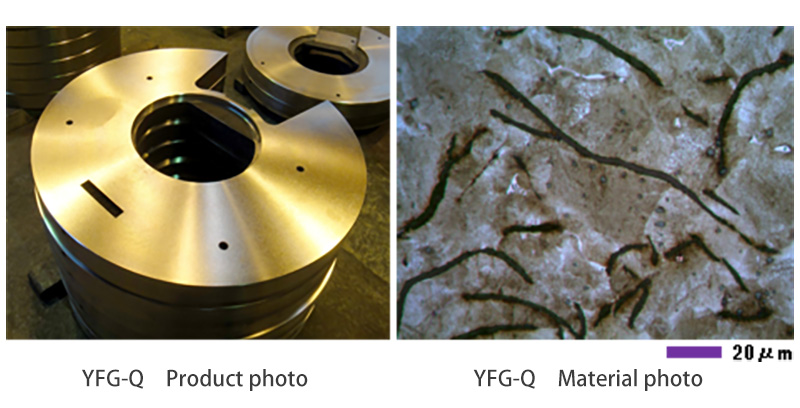

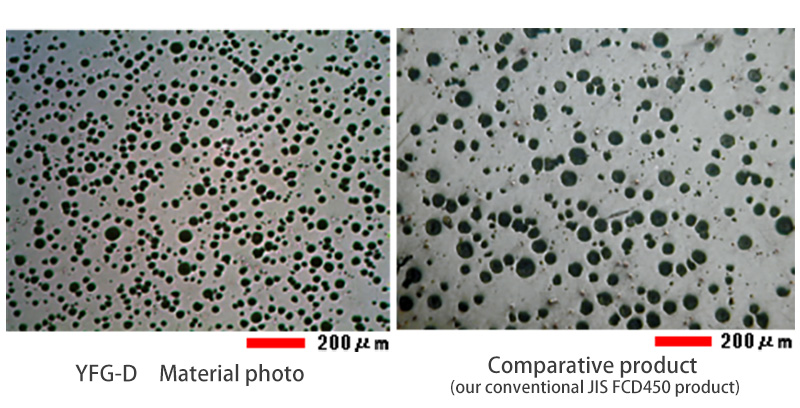

This material has finer graphite, a larger number of graphite grains, and more homogeneous graphite grains than conventional spheroidal graphite cast iron. In comparison with general material equivalent to JIS FCD 450, elongation was greatly improved while securing tensile strength. Although this material is currently provided as a raw material for plates for the final finish process of grinding ball bearings, an improvement in performance is expected by applying it to all FCD material products.

| Tensile strength (N/mm2) | 450-470 |

|---|---|

| 0.2% proof stress | 300-320 |

| Hardness (HB) | 150-170 |

| Elongation (%) | 20-25 |

| Number of graphite grains (per 2) | 250+ |

*Test results by separately sampled test pieces (Y block of JIS Type B)

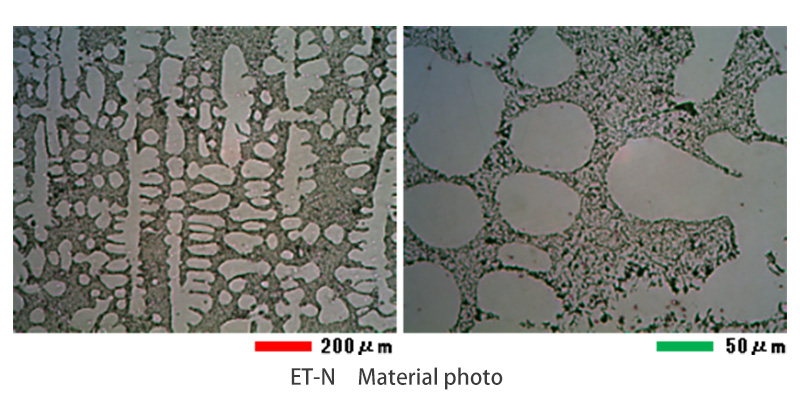

This material has been developed for the final finish process for grinding ball bearings. Homogeneous distribution of ultrafine graphite contributes to the improvement in precision and surface roughness of the product to be ground.

| Hardness of actual product (HS) | 18-22 |

|---|---|

| Maximum castable wall thickness(mm) | 50 |